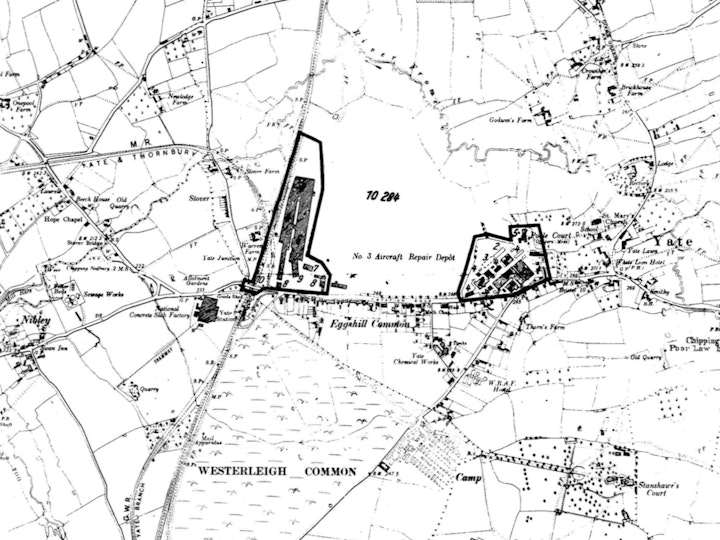

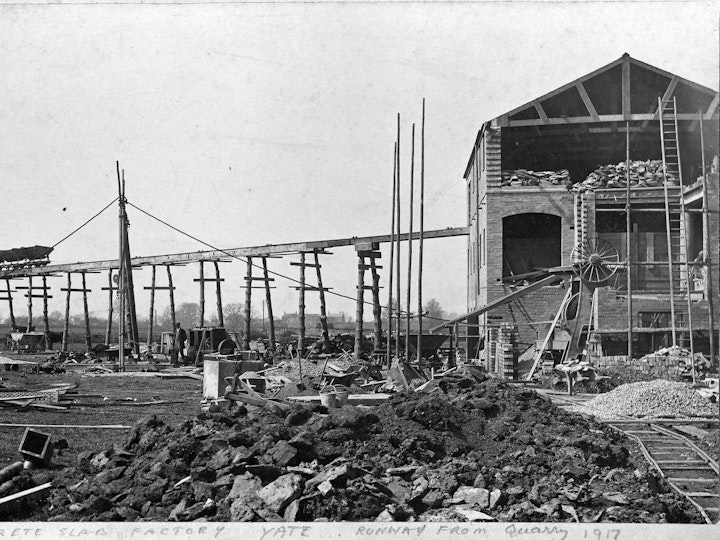

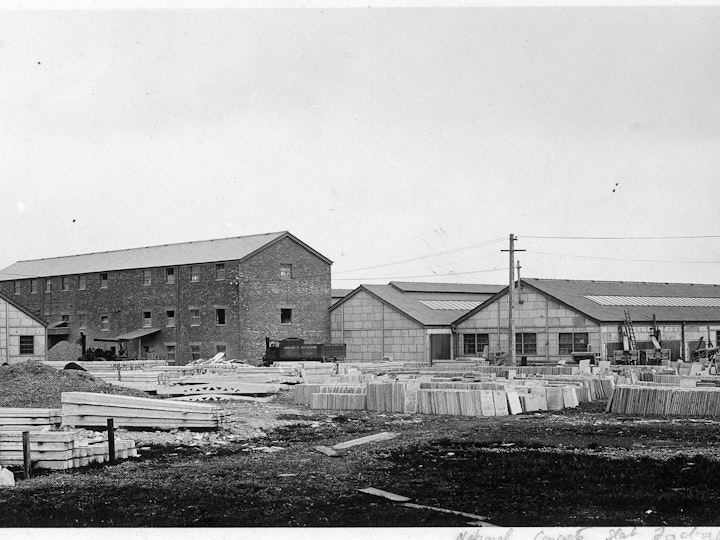

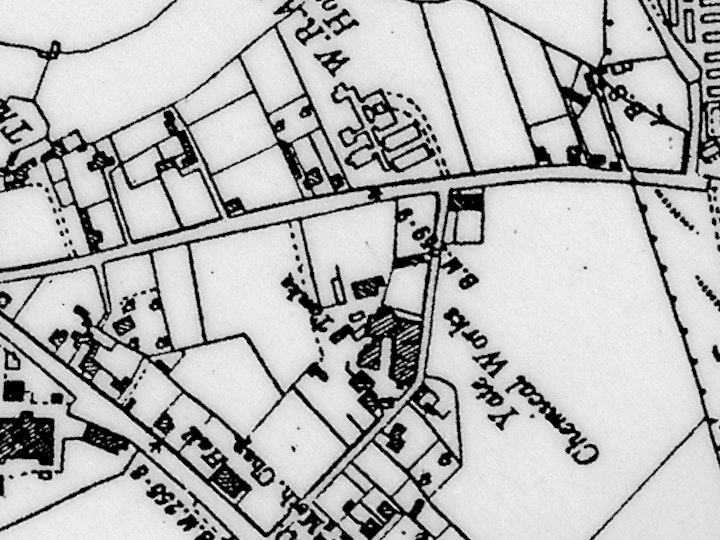

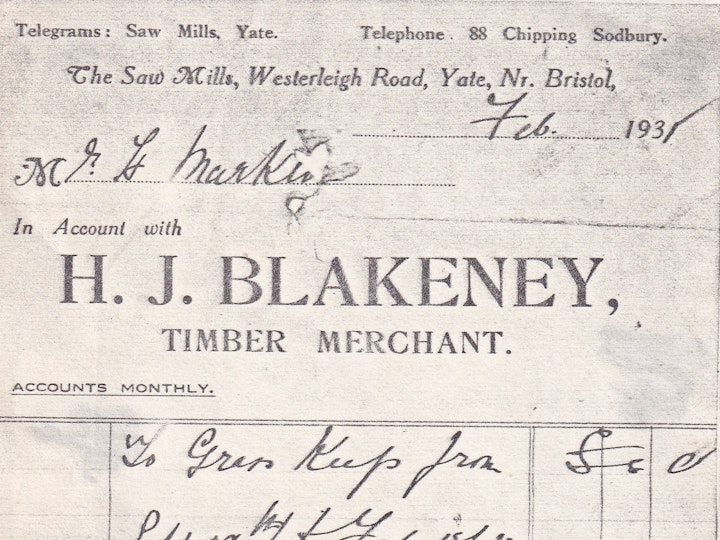

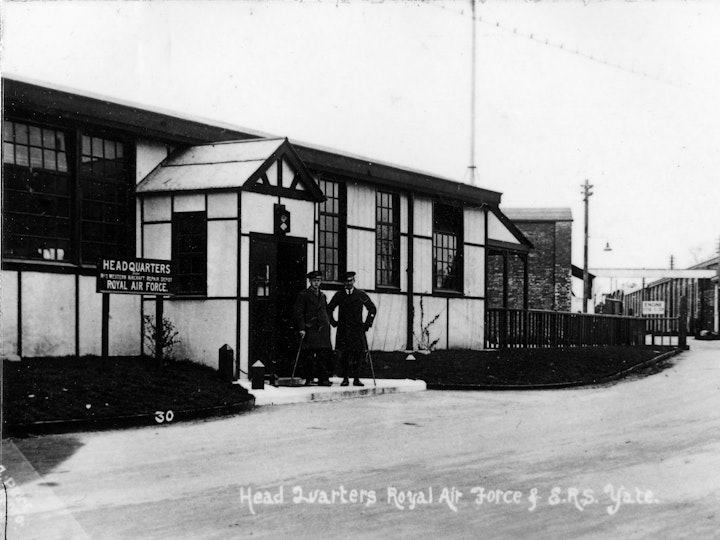

Manufacturing on a modern scale began in earnest after the end of World War I when the ARS and ERS facilities as well as the POW interment camp on Westerliegh road were purchased by existing Bristol based companies to expand their manufacturing capacity by making use of the extensive industrial facilities and infrastructure developed prior to and during World War I.

George Parnall & Company took over the former ARS

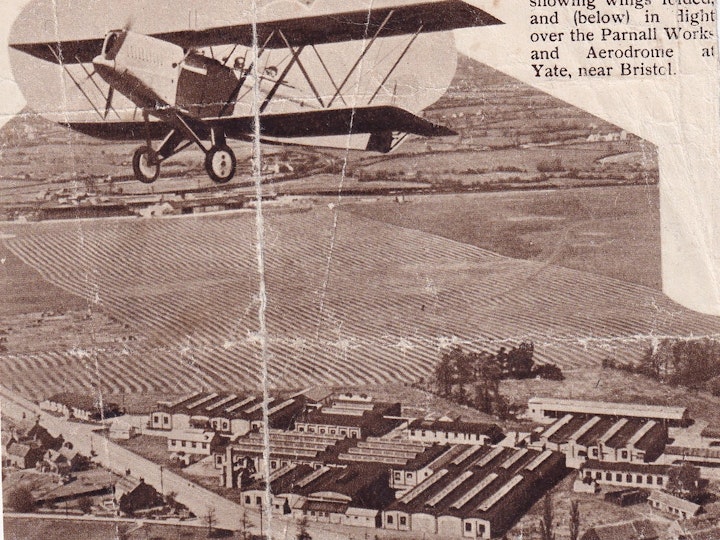

George Parnall & Company took over the former ARS and aerodrome adjacent to Yate Station. Between then and 1930 his firm built a number of prototype experimental naval aircraft of their own design. These included the Perch, a two-seat trainer, first flown from their new airfield in December 1926; the Pike, a dual role reconnaissance machine; the diminutive Peto, a submarine-borne spotter plane; the Pipit a single-seat fighter; and the Prawn a single-seat flying boat.

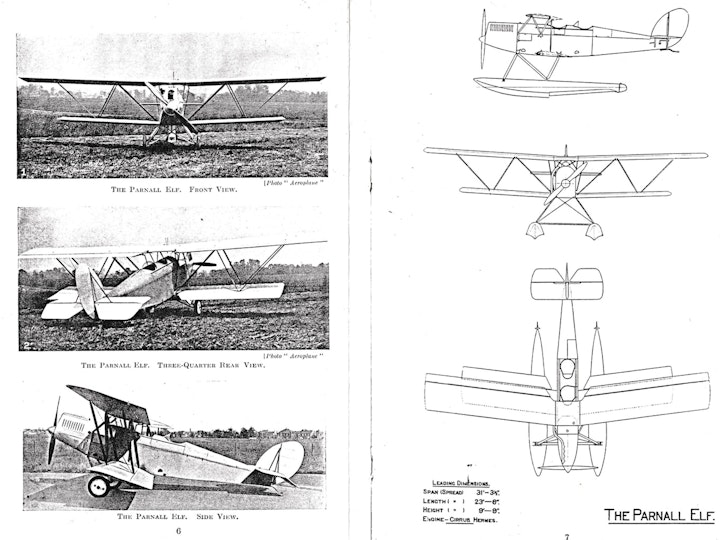

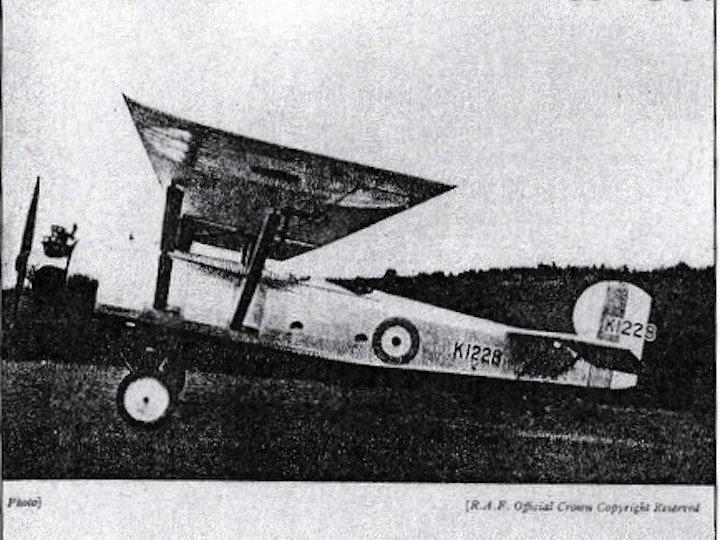

In 1926 George Parnall & Company obtained a contract for the refurbishment of 18 de Havilland DH 9A biplanes for the R.A.F., and this was followed by a contract to build a batch of 12 De Havilland DH 9A dual-control trainers, again for the RAF, while in 1927 they completed a single Imp biplane intended for private or sporting use. This was followed by two Elfs of somewhat similar design, and in 1931 by the Parasol, a research aircraft for the Air Ministry which was capable of testing wing characteristics in flight.

Another aeroplane designed to meet an Air Ministry specification was the Parnall G4/31, a prototype general purpose biplane, although this was not flown until 1935. Between 1929 and 1934 the company also constructed a few aircraft for other designers, such as two Autogiros, a Hendy 302 sporting monoplane, a small sporting biplane known as the Miles Satyr, and 23 Percival Gull three seat cabin monoplanes.

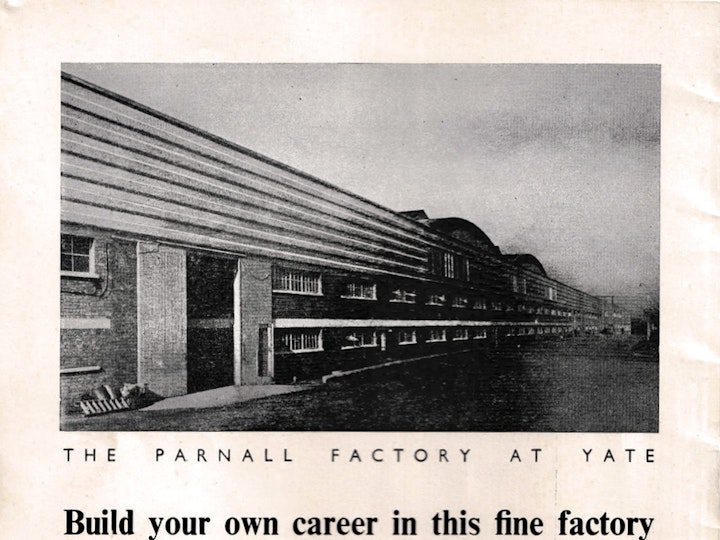

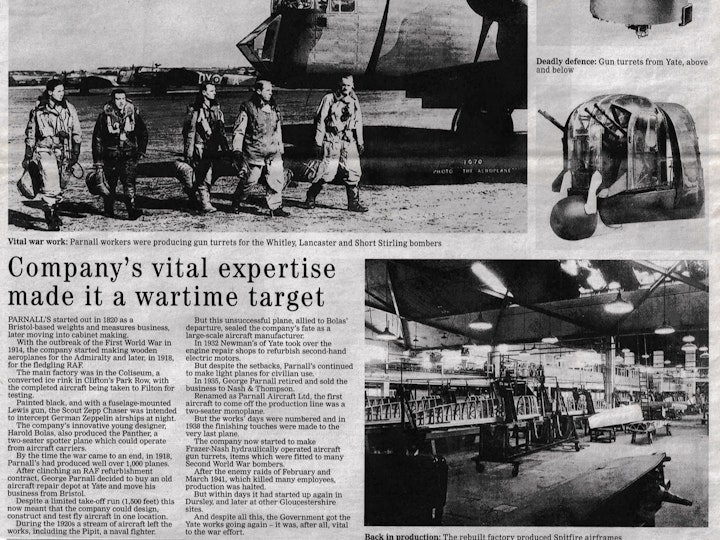

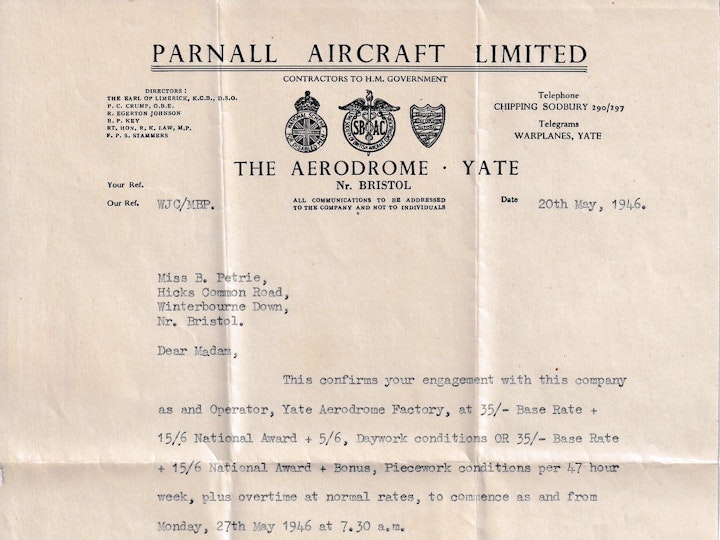

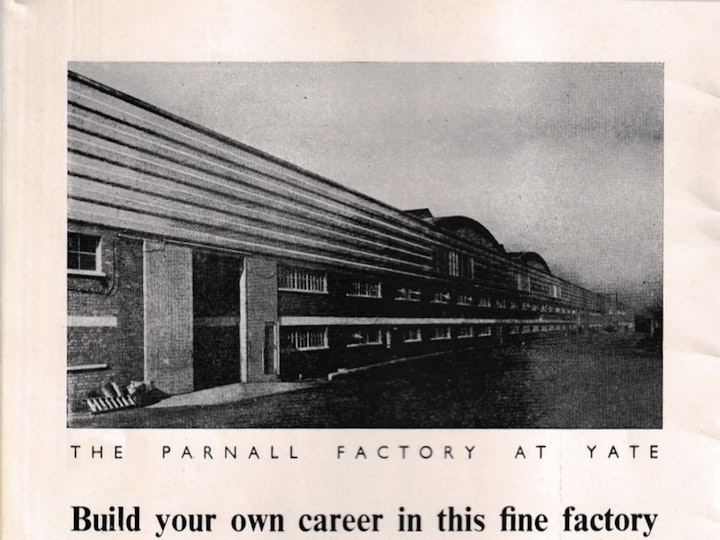

In 1935 George Parnall sold Yate airfield and the remaining buildings, to Nash & Thompson Ltd. of Tolworth in Surrey, which together with the Hendy Aircraft Company, set up a new undertaking at Yate to be known as Parnall Aircraft Ltd, which was incorporated on 23 May 1935. After building the Parnell Heck, the last of which appeared in 1938, aircraft production ceased as the new company's main interest switched to power-operated gun turrets which were to equip such bombers such as the Whitley and Wellington, as well as the Blackburn Botha reconnaissance bomber and torpedo aircraft and the Sunderland flying boat. Consequently, a large new factory was built alongside the railway line in the south-west corner of the Yate airfield, and this was in full production by late 1939.

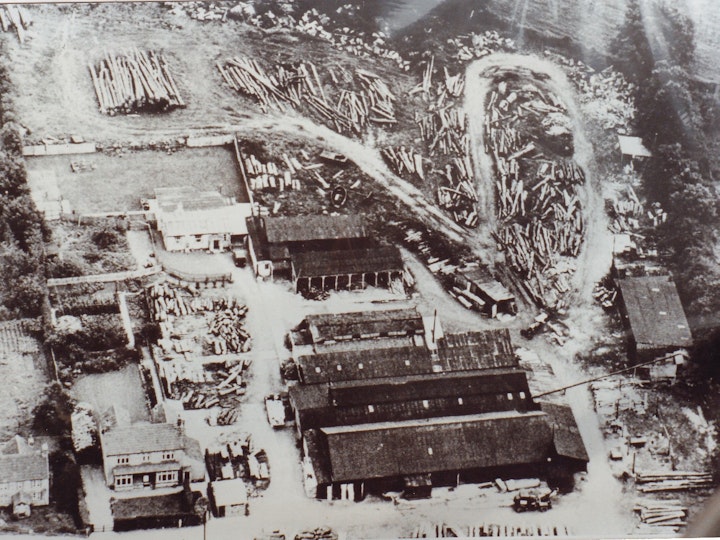

Just prior to the outbreak of war the Luftwaffe's elite strategic reconnaissance group, using aircraft painted in Lufthansa colours pretending to be carrying out route proving flights, secretly flew over a number of potential targets in Britain, and on 29 August 1939 they took a photograph of the Parnall Aircraft factory at Yate. Such images were to be used to help bomber pilots identify their objectives, and the target folders they carried also included maps, which in the case of Britain were suitably re-marked extracts from pre-war Ordnance Survey publications!

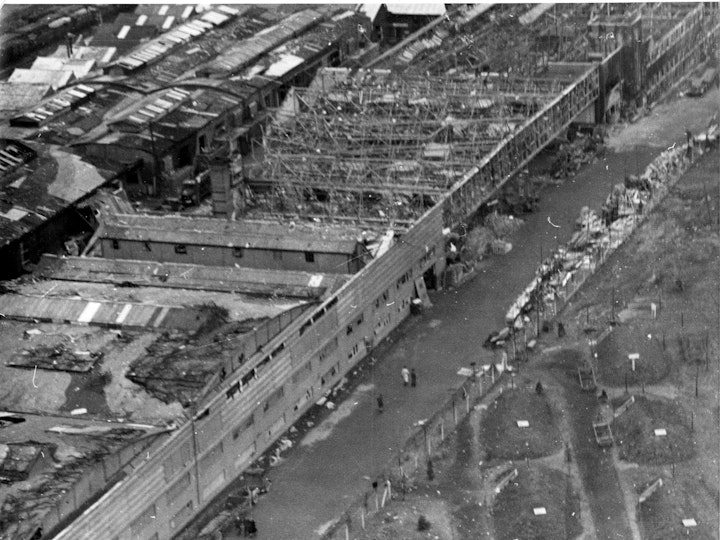

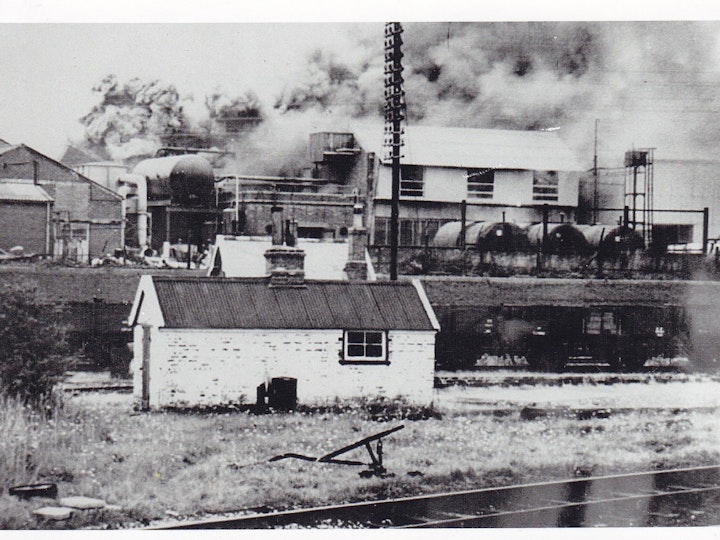

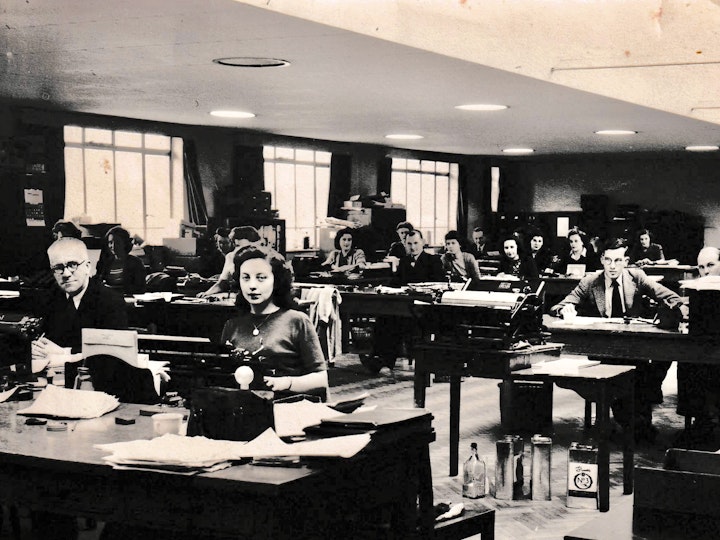

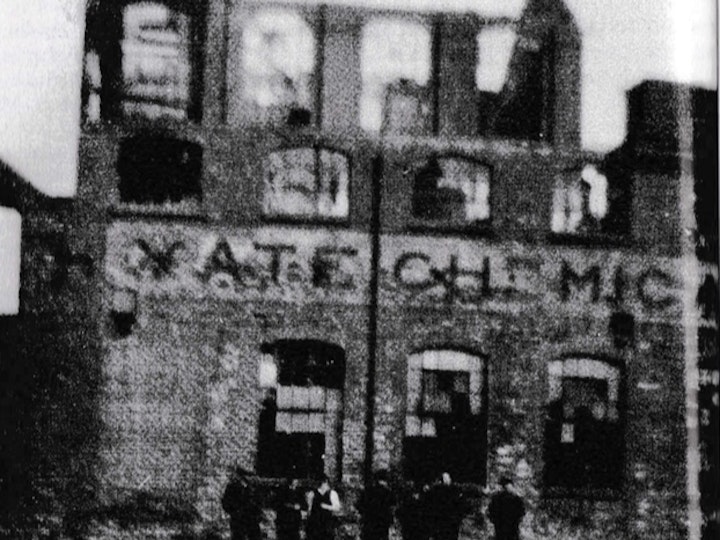

As the main producer of Frazer-Nash gun turrets, the Yate works of Parnall Aircraft was an obvious target for the Luftwaffe. Nevertheless, although a total of 19 bomber sorties were flown against the plant by day night and dusk on seven occasions between 1 August 1940 and 22 February 1941, all either failed to locate their objective, aborted their missions, or were brought down by the local air defences. However, on the afternoon of 27 February 1941 the situation changed dramatically when a lone raider finally reached Yate and released six delayed action bombs over the works. The effect was catastrophic, for not only were 53 workers killed and 150 others injured, but considerable damage was also caused to the factory and drawing office.

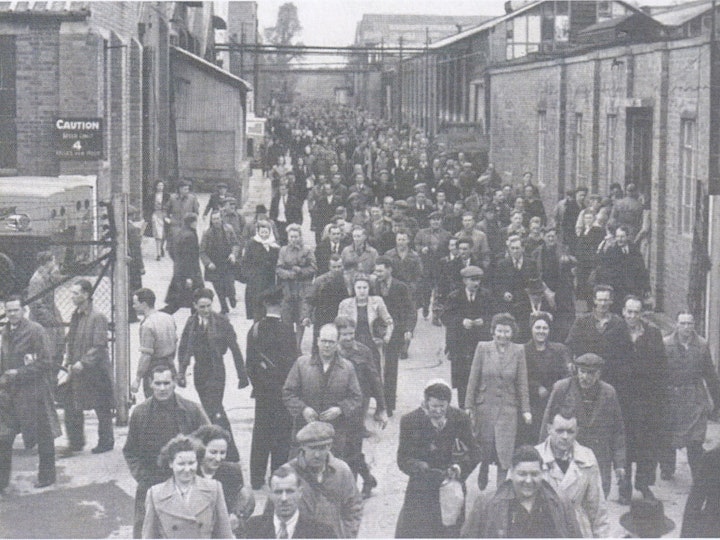

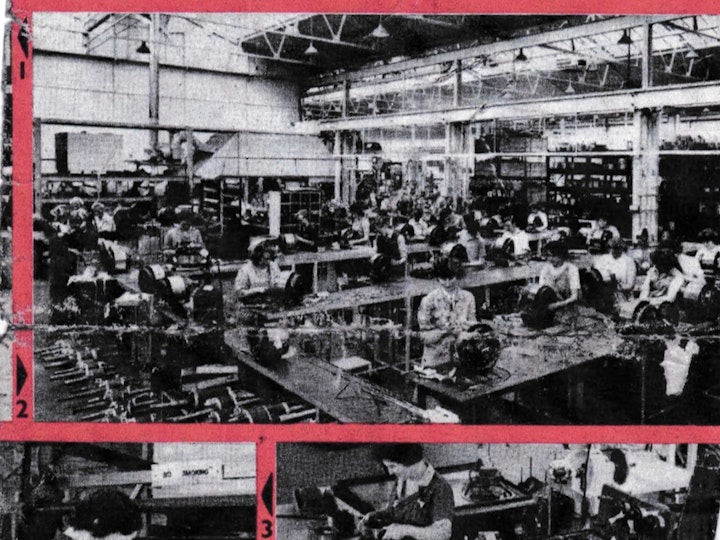

Amazingly, the same crew returned on the afternoon 7 March, but although on this occasion only three workers were killed and 20 injured, such was the additional damage inflicted that production came to a complete standstill and the Ministry of Aircraft Production immediately ordered the total dispersal of the factory to satellite works established all over South Gloucestershire and North Bristol. In spite of this the Yate factory was soon rebuilt, and well before the war ended was back in full production, employing around 3000 people. They were engaged in manufacturing nose and tail turrets for Lancaster bombers, Spitfire airframes and wing components, for which the firm were the country's largest sub-contractor, as well as Lincoln bomber parts and components for the revolutionary Gloster Meteor jet fighter.

When peace finally returned in 1945 Parnall Aircraft Ltd, quickly severed all connections with aviation, and was re-titled Parnall (Yate) Ltd on 31 May 1946. The undertaking then concentrated its efforts on the production of domestic appliances. Of all the products manufactured at Yate after the war, the Parnall washing machine was perhaps the best known, not only in this country, but in some 60 others around the world. The Thor, a spinner type, was introduced in 1947, and three years later production of the Parnall electric self-emptying washer was started. This proved to be one of the outstanding machines of the immediate post war period, and so great was demand that the Yate factory, which was then employing some 1500 people, needed to have its floor space increased.

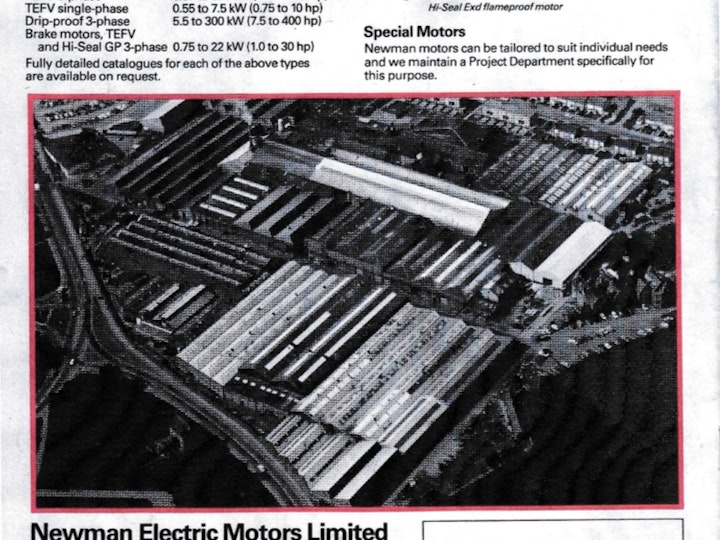

Newman Sons & Company took over the former ERS

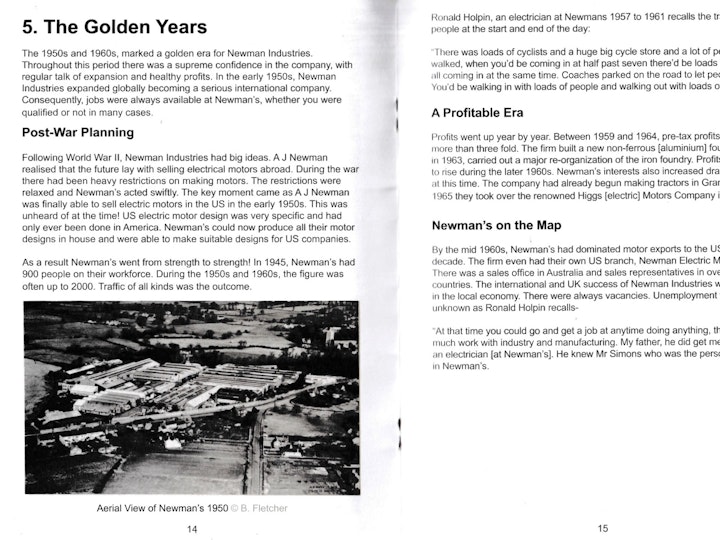

In 1934 the Engine Repair Depot section at Yate, also known as the top works, including both Poole Court and the Depot Guard House which had been used as a drawing office by Parnall’s, was sold to Stephen Newman, father of brothers Augustus James and Hedley, who purchased the premises for £7000, prior to moving their electric motor repair and engineering business from Bristol to Yate. Initially known as Newman Sons & Company, in 1936 it became a public limited company and was renamed Newman Industries, by which time it was employing about 200 people.

The old Depot Guard House later became Newman’s Social Club, while the factory itself remained in production until 1988, when its new owners and old rivals, Brook Crompton Parkinson Ltd, closed it down and sold it to Safeways who demolished it shortly after. However, Poole Court, often referred to as the Guest House by Newman’s employees, escaped destruction and was sold to Yate Town council in 1990.

Hollybrook Brickworks took over the first world war POW interment camp on Westerleigh Common at the junction with Stanshawes Drive.

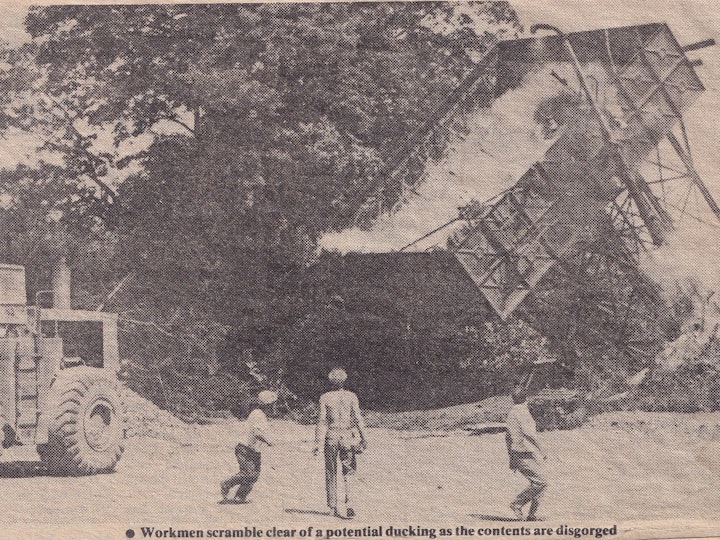

After closure following the end of the war the POW interment camp site went on to become an important part of Yate’s growing manufacturing industry when Hollybrook brickworks moved in during the 1930s in order to expand their production. This was followed by silos and storage manufacturer undertaken by H. Cooper & Sons engineering, which took over after World War Two, the firm having been incorporated in Bristol on 23 March 1953. However, in 2011 it was finally decided to demolish the old 70,000 square feet factory in order to build seventy houses on the site, including a retirement living home named ‘Coopers Court’.